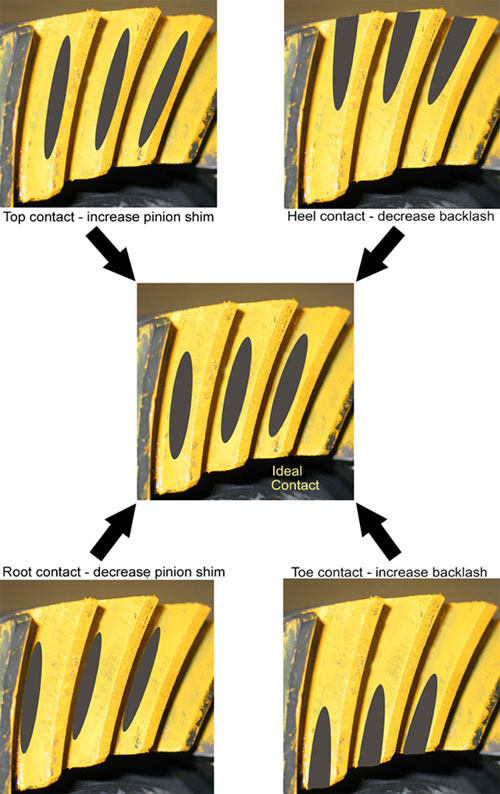

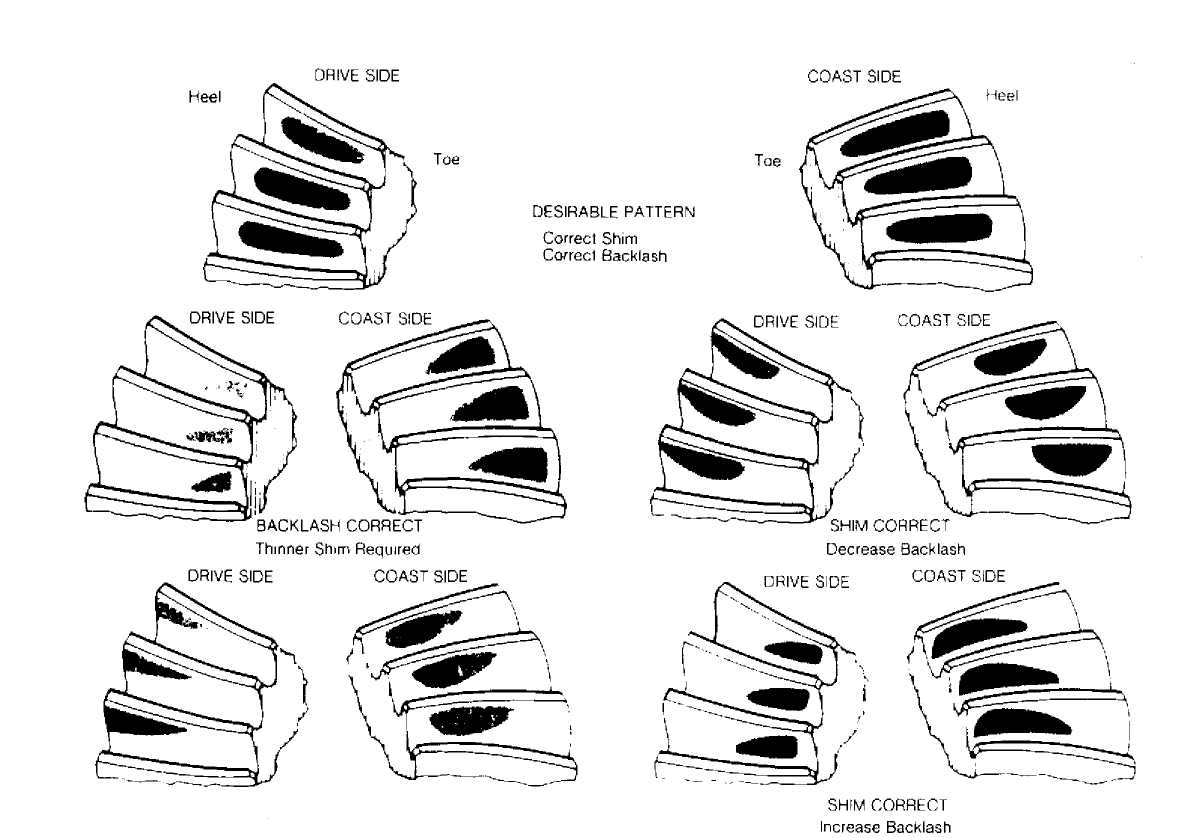

Ring And Pinion Pattern Chart

The heel of the gear tooth is the portion of.

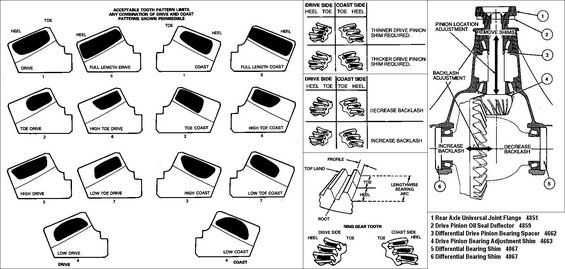

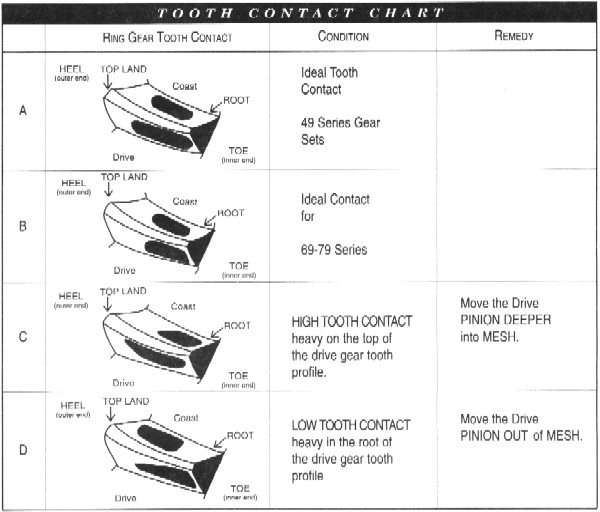

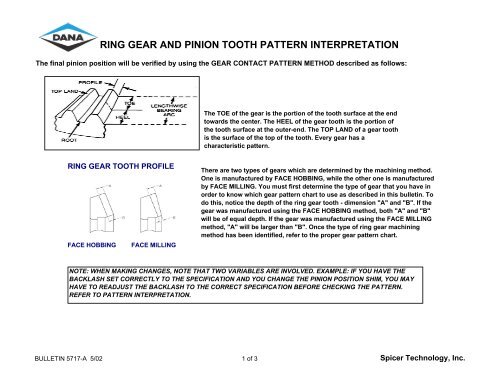

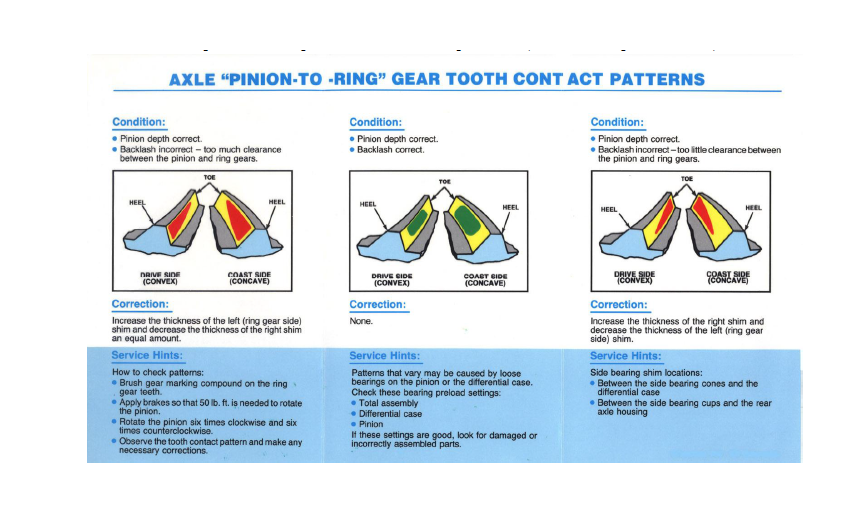

Ring and pinion pattern chart. Ring and pinion gear pattern is one of the most valuable tools for determining if a differential is properly set up. Use gear marking compound to paint all of the ring gear teeth. Move the pinion deeper in towards the differential carrier add pinion shim. Begin by setting proper pinion bearing preload total turning preload and ring gear backlash.

Load the ring gear and run a full contact pattern check. Low contact pattern is concentrated in the root of the drive gear tooth. Moving the ring gear away from the pinion increases backlash and causes the pattern to move out toward the heel of the ring gear. The images below illustrate both acceptable and unacceptable ring and pinion gear patterns.

For more in depth information about ring and pinion gear patterns and how. The ring gear is too far in toward the pinion. Proper ring gear to pinion gear contact pattern is critical for quiet and trouble free gear set operation. When setting the pinion position many of the service manuals required a final pinion position check by using gauges that verified the dimension from the center line of the differential carrier center line of ring gear to the face of the pinion button.

Move the pinion out away from the differential carrier subtract pinion shim. When the pinion is too far in towards the ring gear the pattern is low toward the base of the gear teeth. This pattern indicates excessive pinion depth. Ring and pinion gear pattern interpretation adjustment.