Shell Boiler Level Control System

Opening or closing a relay.

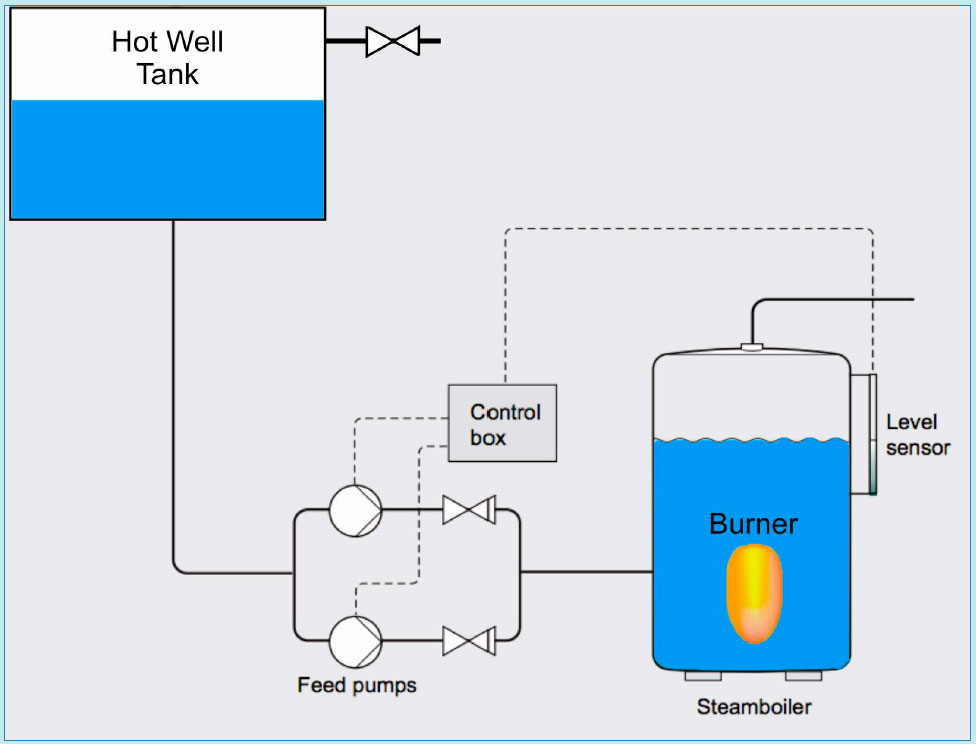

Shell boiler level control system. As it does so the water surface area steam release area will decrease because as the water level is above the centre line of the boiler the sides of the containing shell converge. The system used in steam boilers is very similar. Actions based on probe signals include. Far fewer steam bubbles are formed so water level drops rapidly in the boiler shell.

Level in boiler is high but control is stable. Size of the boiler shell. In horizontal shell boilers the water level rises with increasing load due to the presence of more steam being below the water level in the boiler. Low alarm may sound.

A feedpump an on off level control. A float is mounted in the boiler. The three elements are made up of the following. Advantages of shell.

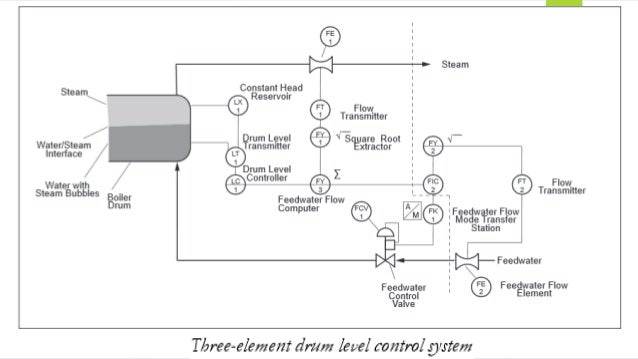

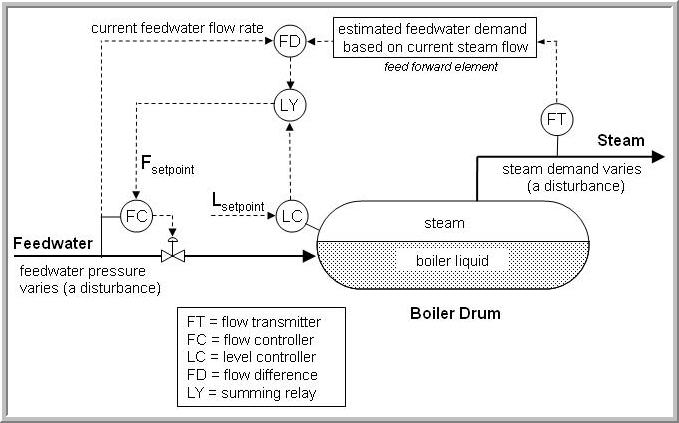

Select the control systems that will support the boiler in supplying dry steam to the plant at the required pressure s and flowrate s. Control in external chamber with low connection or in long length protection tube. Three element drum level control. The three element drum level control is ideally suited where a boiler plant consists of multiple boilers and multiple feedwater pumps or where the feedwater has variations in pressure or flow.

Identify the fuel to be used and if necessary where and how the fuel reserve is to be safely stored. Waves caused by sudden load swings. The next stage is to monitor this movement and to use it to control either. Boiler at high steady load.

Level control systems with sensors or probes that fit inside of a boiler shell or steam drum provide a higher degree of safety than level control systems installed externally. This may be in an external chamber or directly within the boiler shell.