Soft Touch Coating Machine

Our soft touch matte laminating films feature three different adhesive versions.

Soft touch coating machine. 2011 laptop and an external dvd rom drive of a similar age that were produced with a soft touch rubberised external coating on their plastics. It is a matte laminating film with unique properties that deliver the desired. Particularly in automotive interior applications soft touch coatings provide a luxurious look soft touch and leather like texture to plastic surfaces to simulate the feeling of natural leather and improve the aesthetics and haptic characteristics of car interiors according to aditi chavannavar technical specialist transportation industrial coatings with basf dispersions resins north america. I have a couple of items of computery equipment specifically an old c.

These variations in adhesive types enable a wide gamut of application uses. Higher product yield as there is no leftover that is seen from two part systems. Standard thermal adhesive extreme bond adhesive and a high tack pressure sensitive adhesive. In comparison to aqueous coating this method provides better rub resistance and creates a thicker coating for a softer feel.

It comes in handy for applications where the quality of the pencil laser ink marking imprint is important. The effect is highly durable. Soft touch aqueous coating creates a velvety texture with a mellow appearance compared to a glossy finish. Uv soft touch coating is also applied in line on press using ultraviolet uv energy.

It has a 6 12 month shelf life long gone are the days of same day shelf life for current uv soft touch coatings in the market today. Our new uv soft touch has several highly unique characteristics that will certainly set itself apart from the competition. It can be applied as a clear translucent topcoat over a wide variety of substrates and basecoats to produce a lustrous full matte finish. This coating is receptive to pencil ink and laser.

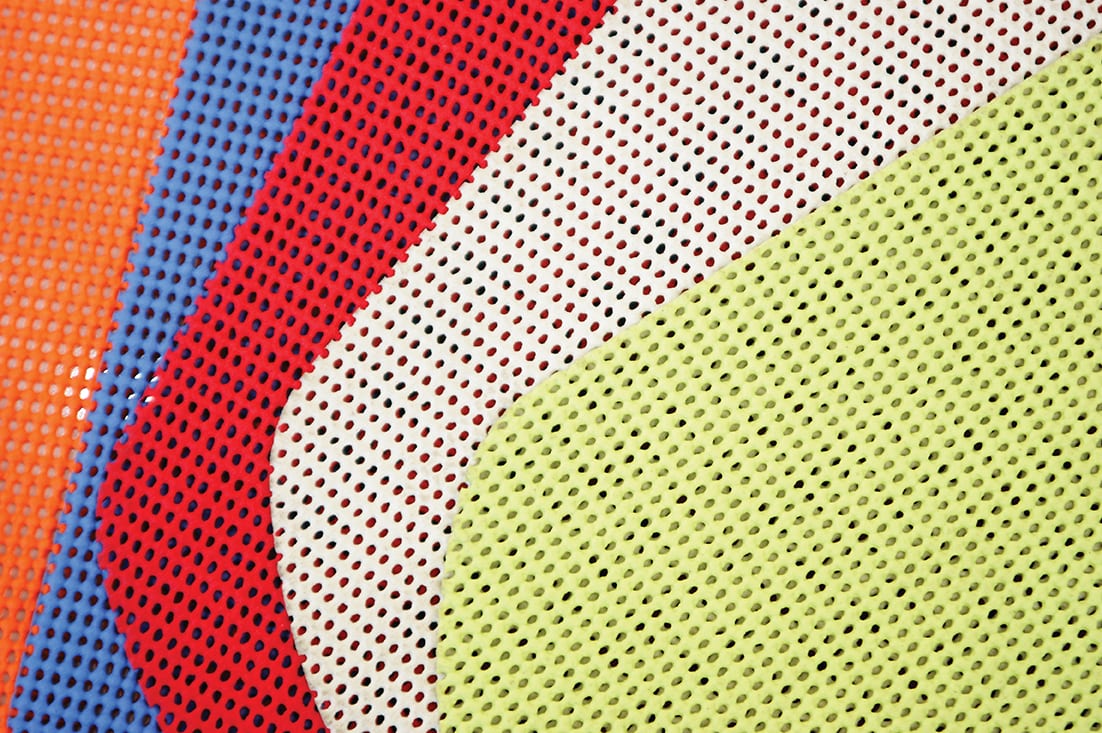

Soft touch laminating films features our soft touch velvet matte finish base film. Brand new v350 laminator four rollers hot roll laminating machine 220v or 110v duration. The kompac chambered anilox roller system allows users to easily apply soft touch and matte coatings to sheets or web. Soft touch lamination process is similar to matte and gloss lamination except for the use of bi oriented polypropylene film or bopp which has a unique tactile finish a soft texture and a matte look.

Chambered anilox co exists with standard coating unit. The surface needs to be cleaned and if necessary polished 800 grain. Soft touch coating on the kompac ez koat 20 plus duration. Qishan luo 98 898 views.

Soft touch coatings can be applied on any paintable substrate. The preparation of the substrate is crucial for the perfect final surface. My new laptop has the same thing on its palmrest and deck and my three year old or so mouse has it too. Or mix with.

Improved quality control management. The coating itself is transparent and can be combined with other coloured or non coloured coatings. It is a one part system no risk of improper mixing compared to current two part systems.