Solenoid Switch Valve Stuck In Low Reverse

As all these possibilities are expensive have the proper testing done.

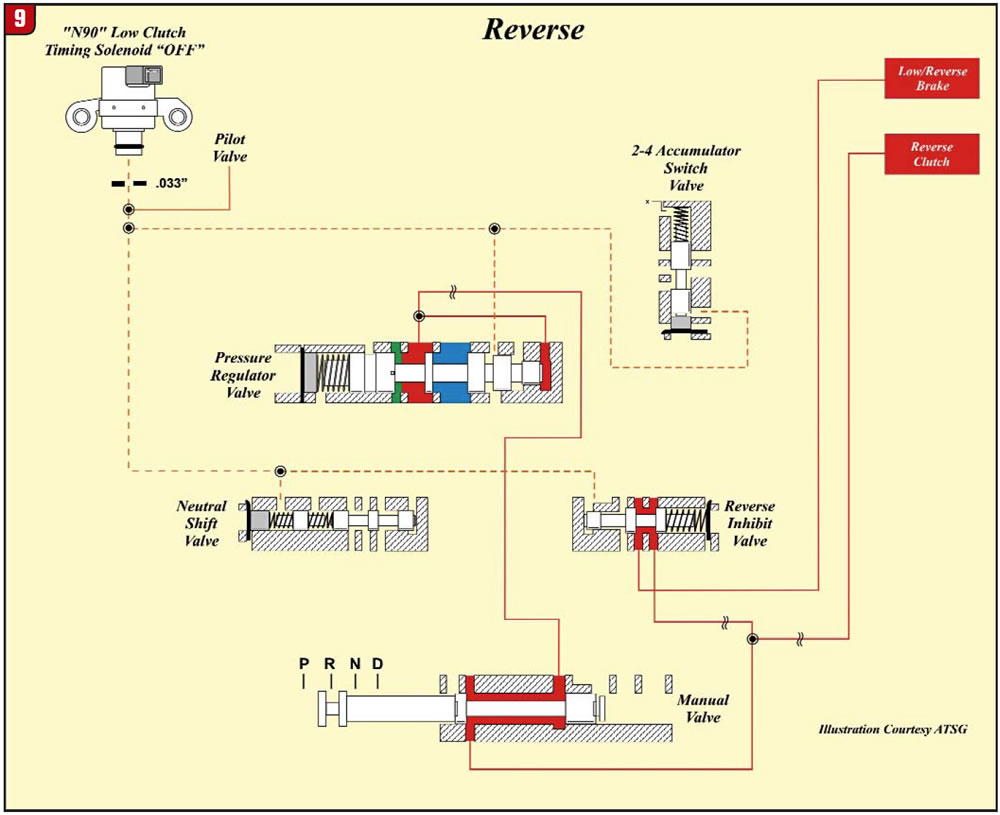

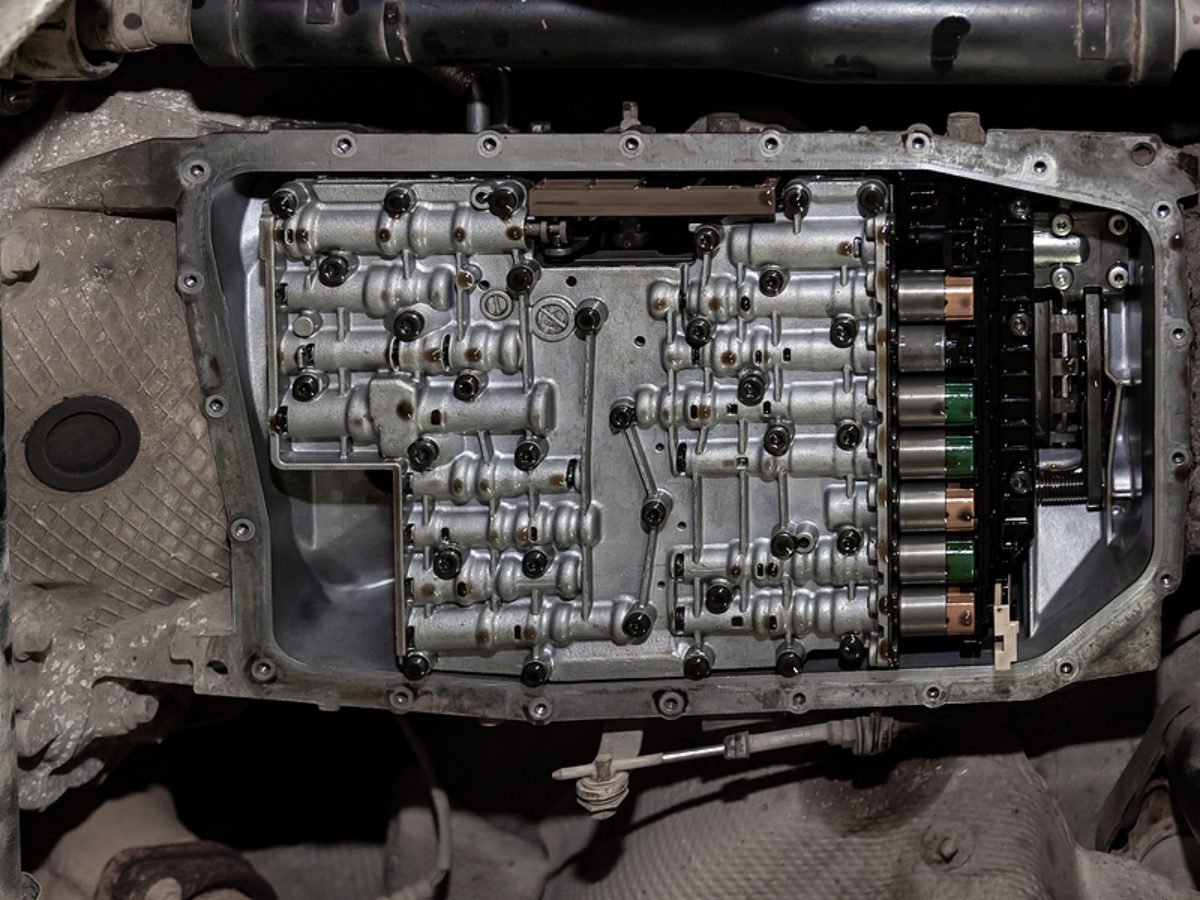

Solenoid switch valve stuck in low reverse. With the drbiiit check the eatx dtc event data to help identify the conditions in which the dtc was set. Immediate failure due to case direct clutch drum or piston breakage. Nine times out of ten these conditions can be traced to electrical or low on charge problems. One cause of shift solenoid malfunction is if the solenoid itself becomes stuck though a plugged valve can also result in various issues.

On a 300m it is usually a failed transmission solenoid pack solenoid switch valve latched in the low reverse position. Dtc p0926 gear shift reverse actuator circuit low. Solenoid switch valve latched in the low reverse position. 41te code dtc p1781 od pressure.

If the reversing valve is in the wrong position they assume it is faulty. Flypig relay winch motor reversing solenoid switch for. In reverse 600 800 psi is common. Ufp by dexter electric reverse solenoid valve with fittings ufp 34500.

Free shipping by amazon. 41te code dtc p0927 gear shift reverse actuator. Dtc p0756 shift solenoid b performance or stuck off 2 3 shift solenoid valve performance. Transmission code p1776 solenoid switch switch valve latched in low reverse position most of the time it is either a solenoid switch valve stuck internal trans part internal trans failure requiring overhaul or pcm failure.

Get it as soon as thu oct 1. 41te code dtc p0757 shift solenoid b. Valve doesn t reverse they assume it is faulty. Valve is located in valve body not solenoid body.

Stuck pressure control solenoid valve located in solenoid. Code p1776 is solenoid switch valve latched in low reverse position. Intermediate od low reverse solenoid 03 up 4 4 out of 5 stars 10. In reality these judgments usually are the result of faulty diagnosis not faulty valves.

41te code dtc p1776 solenoid switch valve latched in lr position. Identify these failures by the symptoms they produce. On a 300m it is. 3 8 out of 5 stars 8.

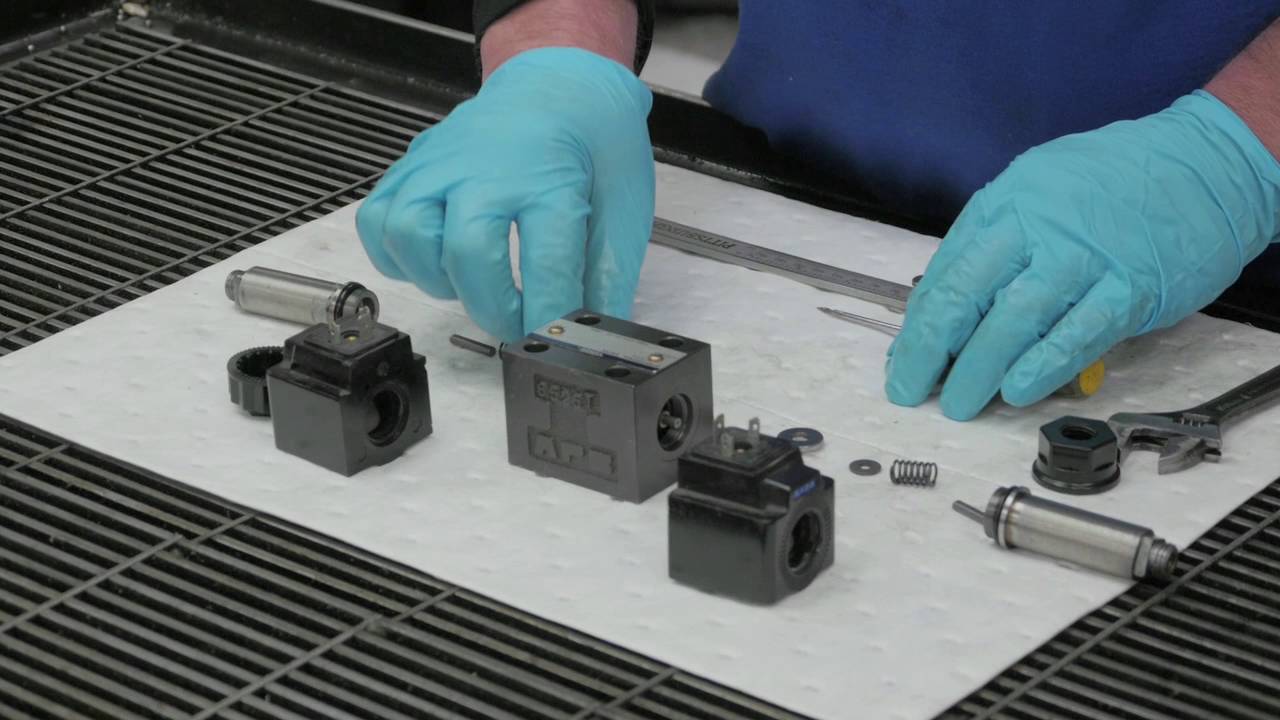

Only 12 left in stock more on the way. The solenoid plungers are constantly bathed in fluid from the transmission and metal salt from the manufacturing process and normal wear as well as detritus from the friction materials can collect on the plungers and cause them to bind in their bores and fail to function properly.