Spirolox Retaining Rings Pdf

Spiral internal retaining rings.

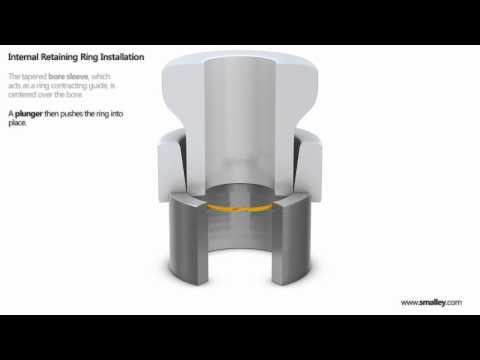

Spirolox retaining rings pdf. Retaining rings spirolox retaining rings have no ears to interfere in your assembly. These coiled rings can be wound into place inside a bore or housing without tools. We carry internal external spiral retaining rings in either carbon spring or 302 316 stainless steel. Spirolox retaining rings meet military and aerospace.

External and internal spiral retaining ring assortments. Smalley s spirolox retaining rings are manufactured by coiling the ring from flat wire and have many advantages over stamped retaining rings and circlips. Choose from our selection of external retaining rings internal retaining rings and more. Spirolox retaining rings meet military and aerospace.

This unique process produces a retaining ring that has no protruding ears or burrs to interfere with your assembly. Arcon ring is a distributor of smalley spirolox spiral retaining rings. Advantages of spirolox retaining rings. Whm wsm series retaining rings use standard industry groove dimensions and are interchangeable with many stamped retaining rings.

Spirolox retaining rings have no ears to interfere in your assembly. In stock and ready to ship. They have a uniform cross section or to use our t erminology no ears to interfere within an assembly and ar e free of burrs. Retaining rings spiral rings constant section rings.

Because coiling produces a retaining ring with no scrap the spirolox ring can be. No gap full 360 retaining surface. Because coiling produces a retaining ring with no scrap the spirolox ring can be. The whm wsm series spirolox retaining ring is designed for the toughest retaining ring jobs.

This unique process produces a retaining ring that has no protruding ears or burrs to interfere with your assembly. They have a uniform cross section or to use our t erminology no ears to interfere within an assembly and ar e free of burrs. Retaining rings unlike die stamped circlips retaining rings spirolox retaining rings and constant section rings are coiled on edge to the exact diameter required. Thicker than standard spiral rings these rings withstand greater forces.

No protruding lugs to interfere with mating components uniform cross section economically produced in. Spirolox rings are manufac tured by coiling the ring from flat wire. This series should be specified for thrust loads that demand deep groove heavy section capacity.